Planning, installation and maintenance of crane air conditioning units

Careful planning creates the basis for a crane air-conditioning unit that meets the application-specific requirements in the best possible way. A predictive installation and regular maintenance ensure that the air conditioning unit cools, heats, dehumidifies and filters reliably even under extreme conditions.

Careful planning creates the basis for a crane air conditioner that best meets the application-specific requirements. Predictive assembly and regular maintenance ensure that the crane air conditioning and filter system reliably cools, heats, dehumidifies and filters even under extreme conditions.

The energy requirement of the crane air-conditioning unit can be reduced by means of cabin insulation

Air conditioning units for crane cabins, crane switch containers, electronic containers and crane control cabinets must perform a range of tasks under demanding conditions and at high temperatures. The following data is relevant for a design that meets requirements:

- Application (e.g. cabin, control cabinet, electronics container)

- Process (e.g. metal processing, port)

- Type and design of the room to be air-conditioned (dimensions, insulation, etc.)

- Minimum and maximum ambient temperature

- Desired room temperature

- Operating voltage in V / Hz

- Control voltage in V / Hz

- Power loss of electrical or electronic installations

Even when planning the room to be air-conditioned, the use of insulation, radiation protection sheets and heat protection glazing can reduce the subsequent cooling requirement and thus the space and energy requirements of the air conditioner. Many crane cabins, switch cabinets and electronics containers are prepared at the factory for the installation of a crane air-conditioning unit with appropriate wall and ceiling openings as well as air connection nozzles.

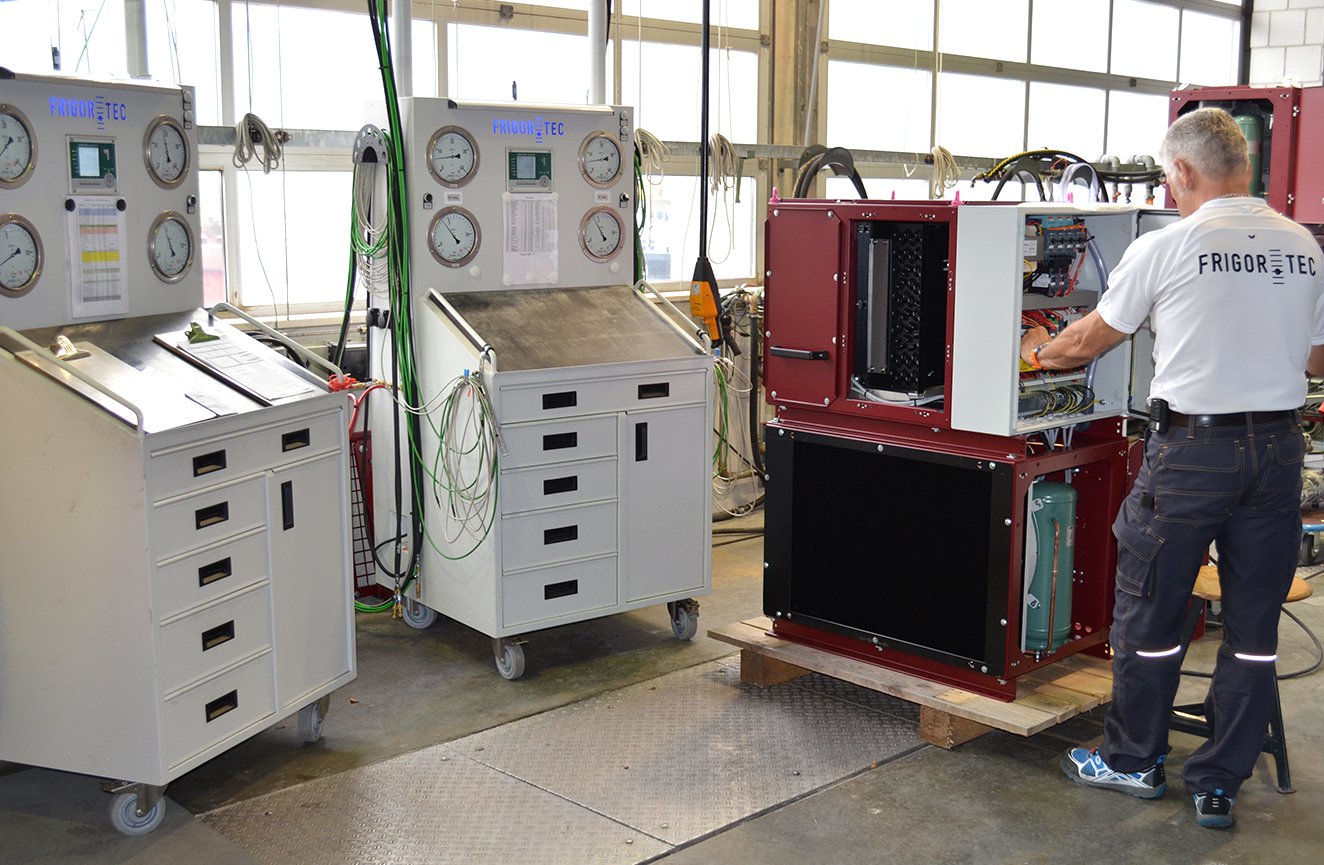

Close coordination with device manufacturers for optimal coverage of all requirements

Close coordination with the device manufacturer for optimal coverage of all requirements. When planning the crane cabin, container or control cabinet cooling, a sensible air flow should be worked out. The supply air can flow into the room to be air-conditioned, for example via a perforated ceiling or through adjustable grids above the front and side windows. In the case of crane control cabinet cooling, the cold air is usually blown in at a low level, absorbs the heat from the electrical components, rises as a result and is carried away by the crane air-conditioning unit. Additional air distribution makes sense for large control cabinets, containers and electronic containers.

When choosing the right crane air conditioning system and designing an efficient air distribution system, it makes sense to work closely with the crane air conditioning system manufacturer. He also supports the development of a filter concept with which the MAK values (maximum workplace concentration) are not exceeded. Operators also benefit from questions regarding relevant standards (e.g. DIN 40050), special requirements of the operating site (e.g. ATEX / explosion protection), resistance to environmental influences (e.g. resistance to salty air) and space requirements of the crane air-conditioning unit in coordination with the device manufacturer.

Compact devices can be installed by the customer

Crane air conditioning units can be installed in different positions, for example as roof units or on the side walls. In crane cabs, compact devices are often installed as a backpack device on the rear wall of the crane cabin. Compact crane air conditioning units usually enable simple assembly that can be carried out by the customer himself. Split air conditioning units for crane systems generally require a refrigeration technician to be able to install the refrigerant lines properly. For easy maintenance, the crane air conditioning unit should be set up so that it is accessible from as many sides as possible. For major overhauls or repairs, it may also be necessary to completely remove the crane air-conditioning unit from the crane. Other design variants, on the other hand, allow an inspection from inside the crane cabin.

Installation influences the efficiency of the crane air conditioning unit

The crane air conditioning unit should be set up in such a way that it is protected from direct flying sparks and heat radiation. Air ducts between the device and the room to be air-conditioned should be as short as possible and have few bends in order to minimize the incidence of heat and pressure loss. For efficient heat dissipation, the air conditioning unit should be installed close to the heat source. At the same time, a wall clearance of at least 30 cm is required so that the cooling air for the condenser can flow in and out unhindered. If condensation drains off through a hose, it should be laid as a siphon. As a result, the condensation water forms a barrier that keeps outside air from entering the room.

Vibration-isolated installation is possible for low-noise operation of the crane air-conditioning unit. On the one hand, it prevents vibrations from the crane air-conditioning unit from being transferred to its surroundings and, on the other hand, protects it from vibrations of the contact surfaces. In particular, if the crane air-conditioning device is attached directly to the crane cabin, structure-borne noise transmission to the crane cabin can be reduced by an elastic mounting and a low-vibration and low-noise operation can be achieved.

Regular maintenance of the crane air conditioning unit increases efficiency and availability

Regular and thorough maintenance extends the service life and increases the reliability of a crane air conditioner. Inadequate care, on the other hand, can lead to deposits of dirt on the heat exchangers and clogged filters and reduce efficiency. The condenser and evaporator of the crane air conditioning unit should be cleaned at regular intervals and the filter mats cleaned or replaced. The condensation water hose should be checked and the siphon filled with water.

A regular check of the electronics, wiring and contacts of the device is always useful and helps to ensure explosion protection (ATEX) permanently. Especially in aggressive atmospheres such as salty and corrosive air, the surfaces of the crane air conditioning unit should also be checked regularly for damage. With careful planning, correct installation and regular maintenance, an air conditioning unit for cranes, crane switch containers and crane control rooms can be operated safely in the long term, even under extreme conditions and at high temperatures.

Our products

More know-how articles

When a crane air conditioning unit is necessary

Depending on the location, air pollution and extreme temperatures present challenges for operating personnel and crane electronics. Controlled air-conditioning of crane cabins, electrical rooms, electronic containers and switch cabinets is therefore indispensable in many applications.

Functionality and design of crane air conditioning units

Safety refrigerants are used in crane air conditioning units to ensure safe operation. Additional components expand the air conditioning systems, e.g. with heating and filter functions. Despite their basically similar design, crane air conditioning units can be divided into compact and split units.

Industry specific requirements for crane air conditioning units

Crane air conditioning units are used in a wide range of industries that have a variety of requirements in terms of functionality and resistance to environmental influences. Design adaptations ensure that the units function reliably even in challenging environments.

Arrange a consultation appointment

Our experts will be happy to advise you on the planning and implementation of your projects. Together we will find a perfect customised solution.

Arrange an appointment